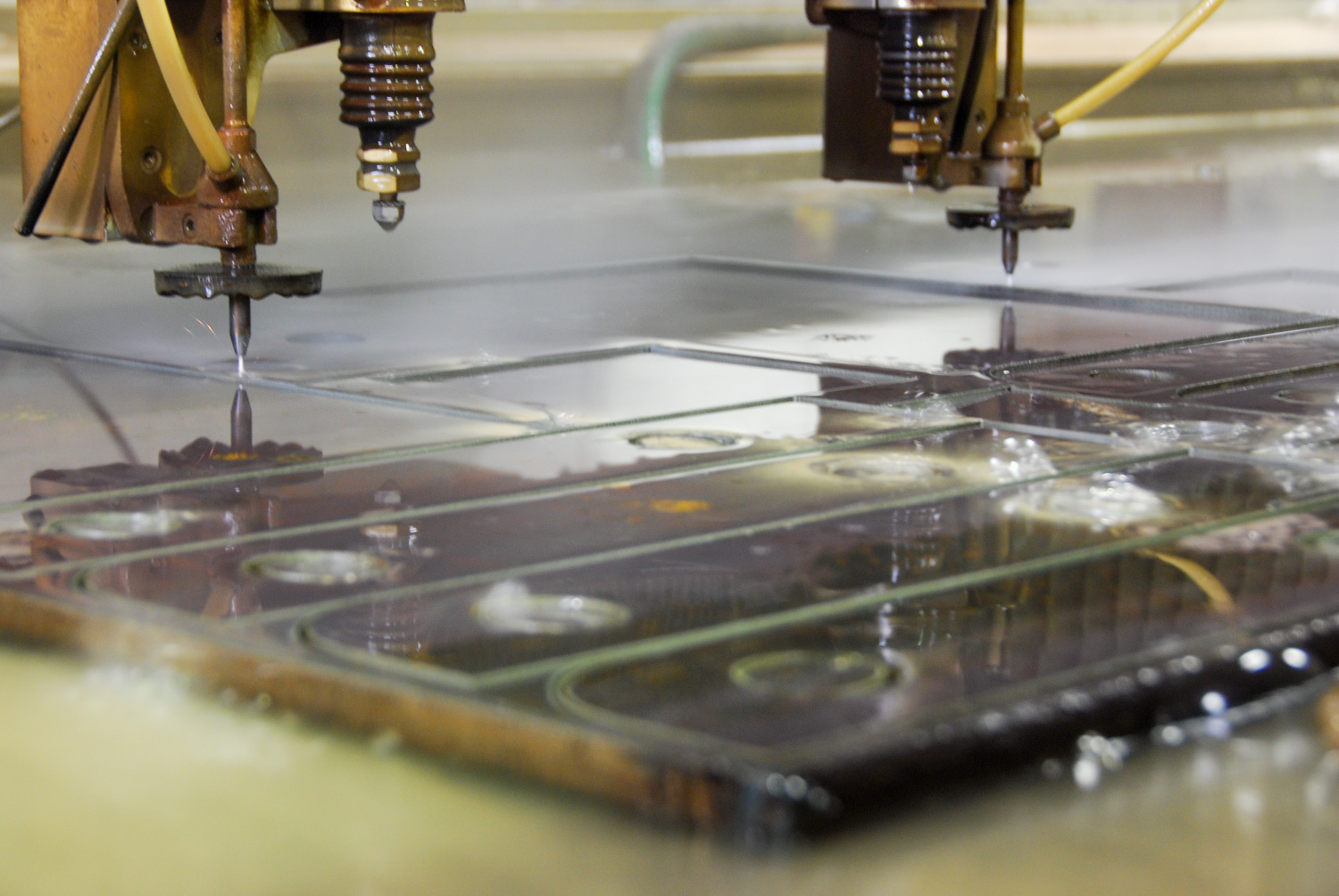

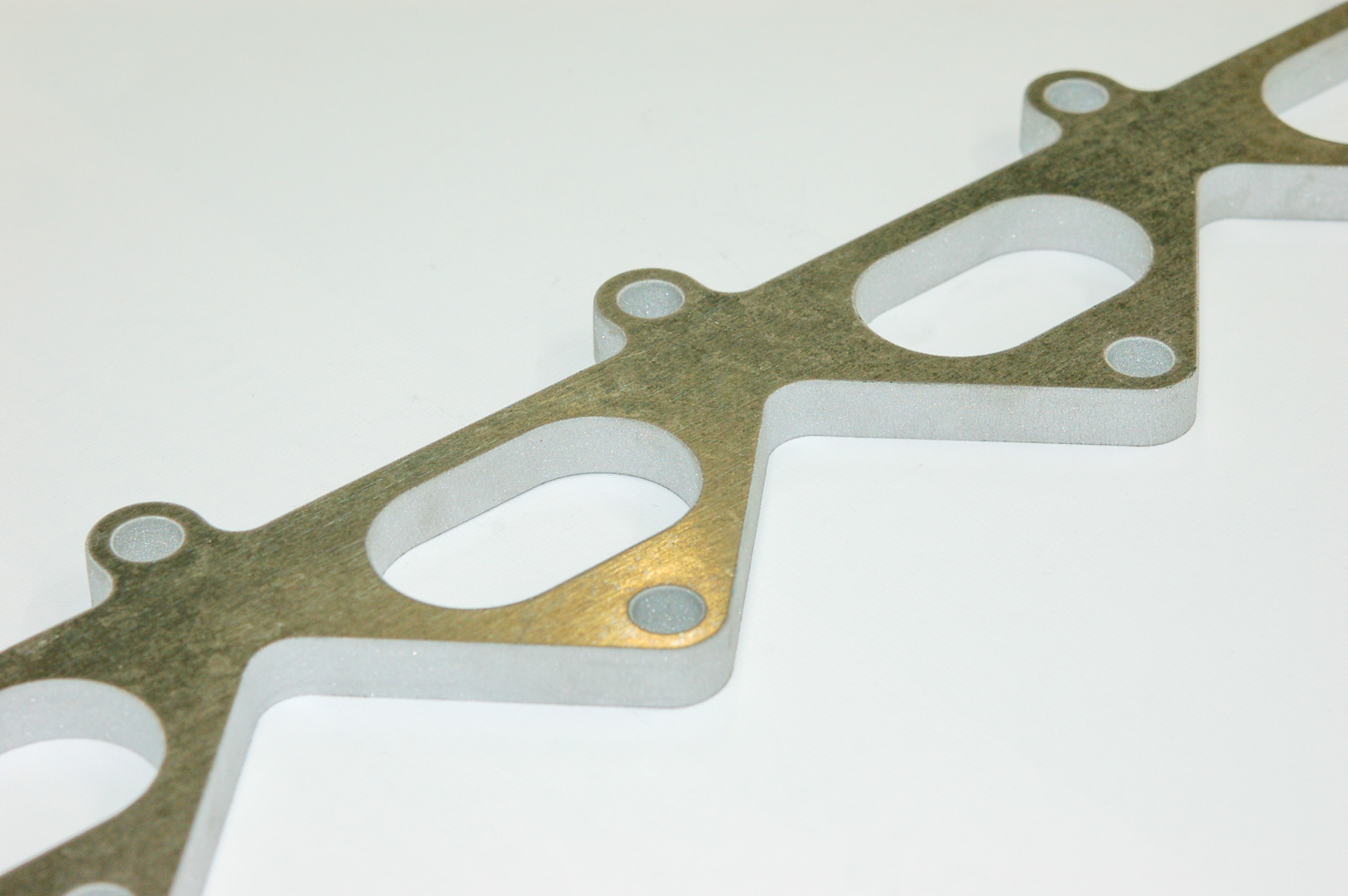

Kilner’s Engineering can waterjet cut a wide array of materials and thicknesses. Exotic materials are our specialty and we can reduce your costs and minimise material wastage through close part nesting. We have an extensive material database which means we can cut all most all materials without the need for test cutting and specialised setups.

Abrasive waterjet cutting works by mixing high pressure water with garnet to create a focused high velocity stream which erodes the material. Unlike other profile cutting technologies waterjet cutting is not restricted by material thickness and grade, the cutting speed is simply adjusted to suit the materials cutting parameters. It is ideally suited to cutting reflective materials such as Stainless Steel, Aluminium, Brass & Copper.

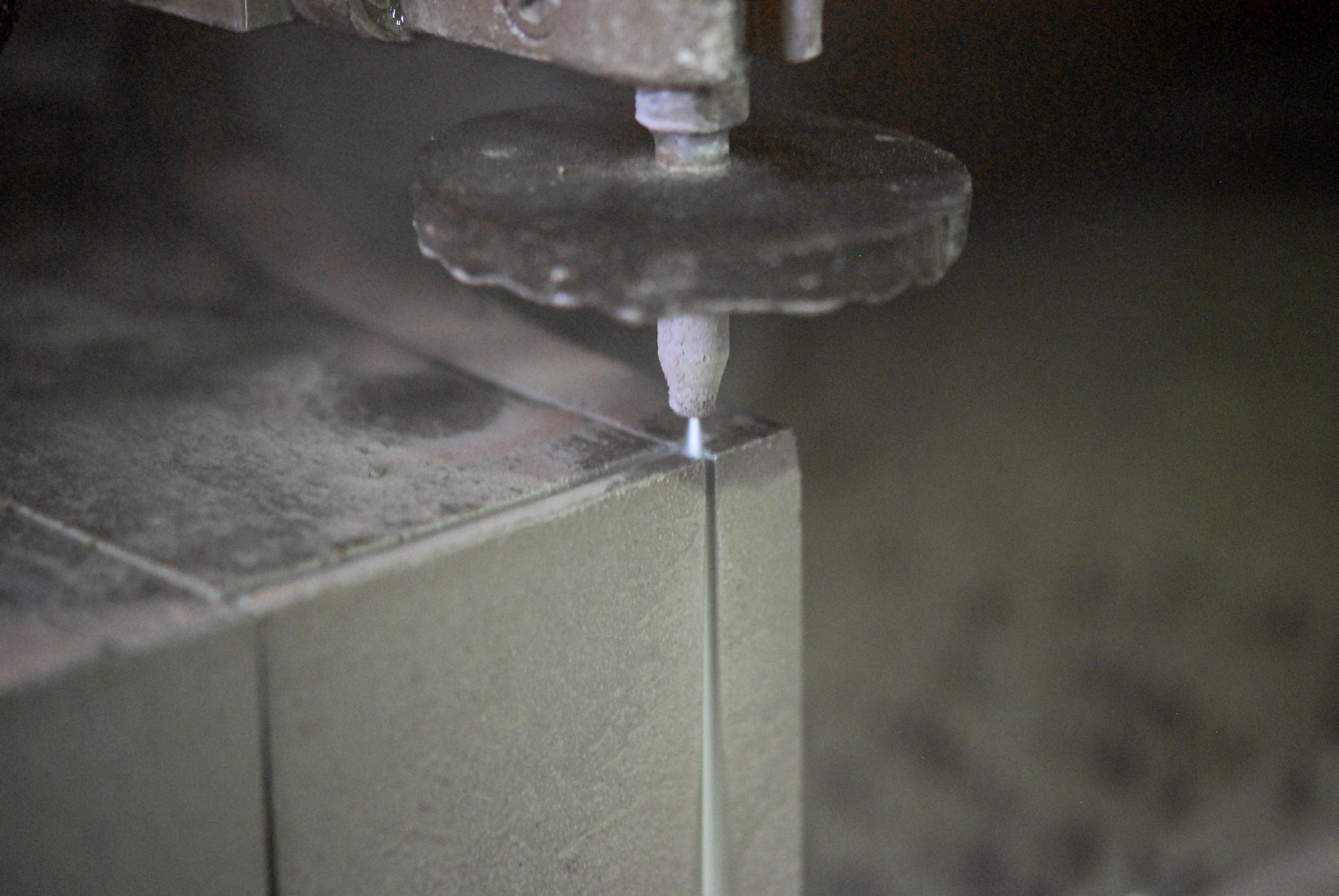

Pure water cutting is another alternative cutting process which we can offer, it is best suited to processing soft materials such as foam, thin rubber, cork and some plastics.